|

Heat treatment may be the most common process during manufacturing, but laser heating is currently only used in a few areas. Heat treatment requires low-brightness large-area uniform irradiation and precise control of heat; these requirements are quite complicated for traditional high-power lasers, while VCSEL arrays are inherently equipped with these capabilities and are easy to operate. Due to fast response capability and low power consumption, Vertical Cavity Surface Emitting Laser Diodes (VCSELs) have been widely used in data communication and sensing applications. By integrating large-area VCSEL array, power density of several W/mm2 can be achieved. These characteristics enable VCSEL to enter the high-power application field and become an ideal heating application solution, such as melting, welding, curing, drying, sintering, etc. Traditional industrial heating, including burners, convection ovens, hot air blowers, microwave ovens, induction heating, halogen lamps, etc., these methods have their specific advantages and continue to play a role in certain fields. However, they are large in size, start and heat slowly, and heat control is not precise. |

Compared with traditional radiant heat sources, edge-emitting lasers and pumped solid-state lasers have higher brightness, but for heating applications, they maybe with too high-power density and too small irradiation area. Through special optical design, homogenization and expansion of the beam, a larger area can be uniformly irradiated, but a complex optical lens combination is required, which makes the system bulky, fragile, and expensive. Just as LEDs are now replacing incandescent lamps and general lighting lamps, VCSELs will also become the next generation of heating lamps due to significantly improved efficiency and reliability. In terms of manufacturing and integrated packaging processes, VCSEL as a heat source and LED as a light source have many similarities, and both have cost advantages. Without any special optical design, VCSEL can provide very uniform illumination and can be scaled to an area of any size. VCSEL does not require fiber coupling system, is very compact, and can precisely control heat. At the same time, the narrow bandwidth characteristics allow VCSEL to match the specific absorption spectrum of material processing. The inherent reliability of VCSEL and the packaging compatible with LEDs provide the system with high reliability and the ability to work in harsh environments. |

|

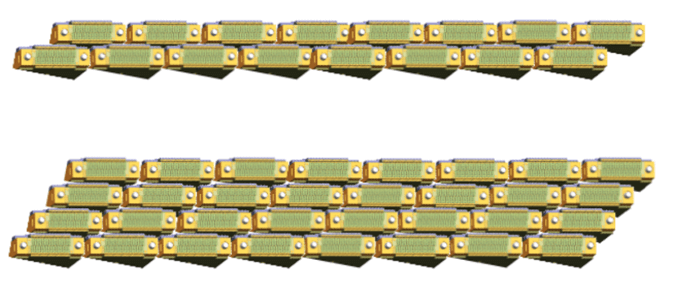

In Figure 3, Brightlaser’s 2D VCSEL array module includes multiple independent chips with a power conversion efficiency of more than 50%, which can provide several hundred watts of continuous (CW) power and more than 1000 W of quasi-continuous (QCW) power. A more powerful chip array can be formed by integrating multiple chips. The VCSEL module shown in the figure 3 above contains 40 chips of 1.5 X 1.5 mm2. The chips are soldered on a ceramic substrate with high thermal conductivity, and then the submount is soldered on a copper |

base for heat dissipation. Forty chips are connected by a circuit in series and in parallel, and the anode pad on the chip is wire-bonded to the pad of the next chip. The two ends of the substrate are Anode and Cathode, which are used to connect to the power supply. This VCSEL module is only 25 X 11 mm2 and can provide a total continuous output power (CW) of more than 300 W.

By stacking the modules in a two-dimensional mode, the total output power can easily be multiplied, as shown in the figure 4 below:  Figure 4 (Source:https://www.researchgate.net/) |

|

Due to its unparalleled superior characteristics, VCSEL array has extended the application of traditional high-power lasers to the industrial heating field. Among them, high performance and low cost are the decisive key factors. Brightlaser provides various standard laser modules with high cost-efficiency. According to the specific requirements ofcustomers, Brightlaser is able to supply various powers, wavelengths |

(650nm-1100nm), addressable, customized and diversified solutions, also cooling system solution applied to the relevant module. The following are some high-power laser module technical parameters and packaging examples for reference: |

|

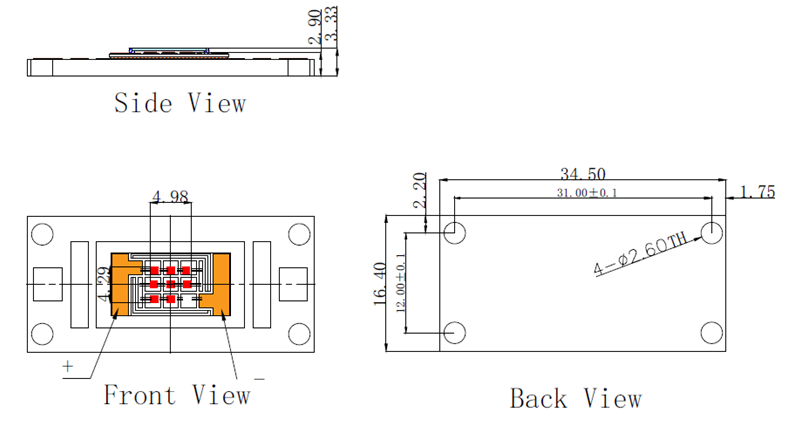

Wavelength: 808nm

Po =20W IF =2.9A VF=17.5V RS=1.8W Emission area= 4.98*4.29mm2 Beam Angle( FWHM)=20° PCE=40% SE=8W/A |

|

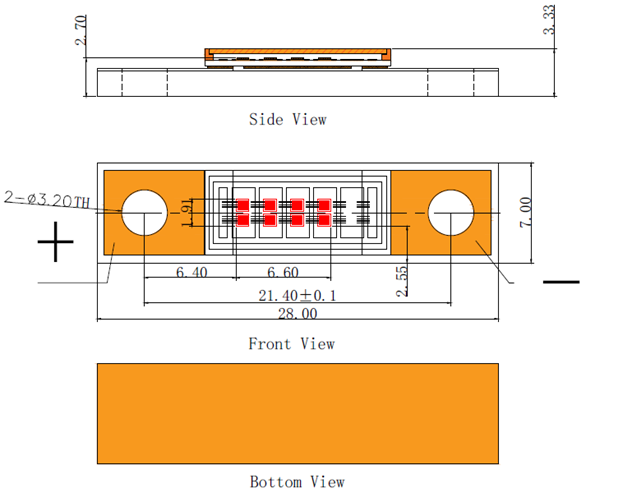

Wavelength: 808nm

Po =20W IF =5.6A VF=8.8V RS=0.39W Emission area= 6.6*1.91mm2 Beam Angle( FWHM)=20° PCE=40% SE=4.2W/A |